Tired of searching for piles in GIS data? With Stockpile Reports, the company knows where your stockpiles are, no clicking required.

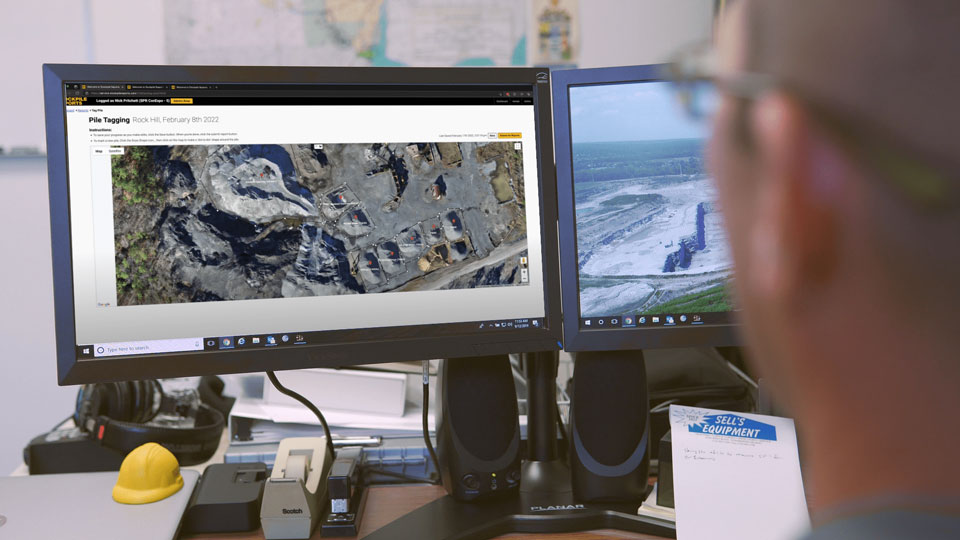

Using automation to generate reliable, precise bulk material measurements is easy with Stockpile Reports. Old school methods and GIS software require manual inputs and fixes to imagery, wasting time clicking on piles and inviting errors. You can put your pencil and mouse down.

“Who wants a cramped finger from clicking on piles with GIS tools?” asks David Boardman, founder and CEO. Boardman believes inventory measurement should be automatic, no clicking required.

“Just like a navigation app where your phone takes you to the right destination, Stockpile Reports removes the guesswork from your inventory data,” Boardman said. “None of this GIS nonsense of hoping to find a pile in the data somewhere. Our system knows there is a pile there and will find it for you. Even better, we give you an independent record rather than a messy estimate. Our solution is simple: load an image from a drone or an iPhone and BOOM! You get a verified measurement and we do this for Every Pile Any Time.”

The question of whether something is a stockpile (or not) is answered with Stockpile Reports, no searching or endless clicking required. Stockpile Reports tells you how much material you have on hand, how much material you had yesterday and helps you estimate how much you will have tomorrow. Data is automatically generated and can be downloaded with a single click or automatically via API integration. No more creating reports, exporting data, and emailing or manually entering inventory values into your ERP.

“Our proprietary algorithms have made correctly identifying piles and products easy with features to associate pile data from prior measurements. We auto-calibrate drone imagery and the pile history is available for comparison and analysis. No need to define the toe or precisely measure pile boundaries: our algorithms remove these risks for you,” Boardman stated.

Periodically, housekeeping is required to make sure piles are properly classified. A few best practices:

- Take 2 minutes and review pile tags for each flight. Piles move and products change, so keep this current.

- Retire piles: Once a pile has been depleted, retire the pile to eliminate inactive piles.

- Check for missing piles: Look for this alert, which can also highlight mis-labeled product.

Stockpile Reports is the only automated, controlled and scalable third-party verification system solution that knows how much material is coming and going, according to the company.